ZeroClamp 4.0

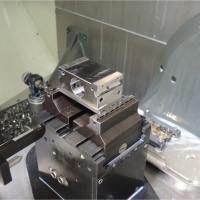

ZERO CLAMP® automation

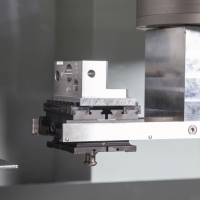

Space-saving system

Optimal utilisation through individual arrangement

of all components within the rack.

Automated clamping devices remove the need for

bench vices and pallets, enabling an even higher

workpiece density to be achieved.

Universal assembly kit

A universal assembly kit is guaranteed with in-house

products for the clamping technology as system

provider :

Manual and automated clamping devices, grippers and

the loading robot from a single source.

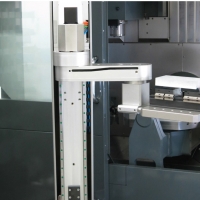

Unique structure

Versatile handling of clamping devices, blank parts,

tools and pallets. The loading robot equips all

necessary components automatically.

The rack holds everything required for production (e.g.

rack fitted with tools only or combined with pallets).

Individual design

Different production orders and quantities can be

handled in one rack in a space-saving way. Automation

can be expanded to up to three racks. Workpiece or

pallet size can be adapted individually to up to 600 x

400 mm (23.6 x 15.8 inch) at any time.

Flexible use

Access to the machine is always guaranteed. Racks

can be pre-equipped during parallel run-time with

minimal personnel effort and transported via a pallet

truck. Loading robot supports the machine operator

in manual operation via the crane mode with 100 kg

(220 lbs) load capacity.

Universal automation

Loading robot can be adapted to a wide range of tool

machines.

One loading robot can be adapted for several different

machine tools.

Fast deployment

Minimal training requirements and easy operation via

an intuitive teach-in function enables fast deployment

of the automation and ensures that operation is

possible even in the event of personnel shortages. The

operation of the loading robot is similar to a CNC

machine.